Temperature and Humidity Control

Supporting customer’s needs for a temporary duration or a lease model basis. With such facility utilities taken care of, customers can focus on their core business. From building services, construction, events, oil & gas, petrochemical and shipping, our equipment and solutions can be mobilized quickly and are versatile across multiple applications.

We have variety of Air-Cooled Chillers and Temporary water-cooled chiller Plants starting from 120 kW to 2,813 kW (34 TR to 800 TR). We offer Turnkey solutions from Engineering Design, Delivery, Installation, Testing and Commissioning as well as dismantling of equipment once the work is over. We are available 24/7 hours during emergency or planned situation. To decide the right solution to your needs, call us to find out more of our solutions.

Effective temperature and humidity control can result in longer life for your operating equipment, higher productivity, and less downtime. Whether you need supplemental, temporary or emergency cooling, Solutions Plus offers a complete line of air-cooled and water-cooled chiller rental solutions to help you maintain seamless operations.

Our broad selection of rental chillers for every size and needs would allow you to focus on your core business be it upgrading your chiller systems, stay up and running during chiller failure, maximize your production during peak and decrease costs by adding capacity only when needed.

Air-Cooled Chillers

Temporary air-cooled chillers find applications in various scenarios where a short-term cooling solution is needed. Here are specific applications for temporary air-cooled chillers:

Server Room Upgrades: Similar to data centers, server rooms in various facilities may need temporary cooling solutions during equipment upgrades, installations, or repairs to prevent disruptions to IT operations. An office building upgrading its server infrastructure might use temporary air-cooled chillers to maintain ideal temperatures in the server room.

Film and TV Production: Temporary air-cooled chillers are used on film and TV production sets to cool equipment, lighting, and ensure a comfortable environment for cast and crew during shoots in various locations. An outdoor film shoot in a warm climate may require temporary air-cooled chillers to prevent overheating of equipment and maintain comfortable conditions for the production team.

Manufacturing Processes: Some manufacturing processes generate excess heat, and temporary air-cooled chillers can be used to provide supplemental cooling during peak production periods or equipment malfunctions. A factory engaged in metalworking may deploy temporary air-cooled chillers during a heatwave to ensure that manufacturing equipment operates efficiently.

Exhibitions and Trade Shows: Temporary air-cooled chillers can be used to provide climate control in exhibition halls and trade show venues to create a comfortable environment for exhibitors and attendees. A large trade show taking place in a convention center may utilize temporary air-cooled chillers to regulate temperatures in different exhibition areas.

Special Events: Temporary air-cooled chillers are often used to provide climate control for special events, such as outdoor weddings, parties, or festivals, where maintaining a comfortable temperature is crucial for attendees’ enjoyment. A wedding held in a tented outdoor venue during the summer may require temporary air-cooled chillers to ensure a pleasant environment for guests.

Emergency HVAC Replacement: In the event of a sudden HVAC system failure or the need for urgent maintenance, temporary air-cooled chillers can be quickly deployed to maintain cooling while the primary system is repaired or replaced. A commercial building experiencing an unexpected air conditioning system breakdown may use temporary air-cooled chillers to prevent disruptions to business operations.

Construction and Renovation: Temporary air-cooled chillers are employed on construction sites or in buildings undergoing renovations to provide cooling for workers and equipment during the construction phase. A construction project in a high-rise building during the summer may require temporary air-cooled chillers to ensure a comfortable working environment.

Data Center Maintenance: Data centers, which generate significant heat from servers and electronic equipment, may require temporary cooling solutions during maintenance or equipment upgrades to prevent overheating and ensure uninterrupted operations. A data center undergoing routine maintenance that involves shutting down part of the cooling system may use temporary air-cooled chillers to maintain optimal temperatures.

Water-Cooled Chillers

Water-cooled chillers are utilized in various industries and applications where temporary or portable cooling solutions are needed. These systems function by removing heat from a specific area or process using water as a heat transfer medium. They are commonly employed when a building’s permanent cooling system is under maintenance, during events, or in industrial processes requiring specific temperature control. Applications of temporary water-cooled chillers include:

Commercial Buildings: During maintenance or repairs of the central cooling system, temporary water-cooled chillers can provide cooling to maintain comfortable temperatures for occupants.

Industrial Processes: Many industrial applications require precise temperature control, such as in manufacturing, pharmaceuticals, data centers, and more. Temporary water-cooled chillers are used to maintain optimal operating conditions for equipment and processes.

Events and Hospitality: For large events, such as outdoor weddings, concerts, or festivals, temporary water-cooled chillers can be used to cool tents, food storage areas, or provide climate control for guests.

Emergency Situations: In emergency situations where the primary cooling system fails or needs supplemental support, temporary water-cooled chillers can be deployed quickly to ensure the continuity of critical operations.

Chilled Water Air Handling Units (AHUs)

Temporary chilled water air handling units (AHUs) are versatile systems used to provide efficient cooling and air distribution in various temporary or special applications. These units are connected to a central chiller that produces chilled water, which is then circulated to the AHUs for cooling the air. Here are several applications where temporary chilled water air handling units are commonly employed:

Event Cooling: Temporary chilled water AHUs are often used to cool large event spaces, such as convention centers, exhibition halls, or temporary structures erected for events. A trade show in a convention center during the summer might deploy temporary chilled water AHUs to maintain a comfortable environment for exhibitors and attendees.

Film and TV Production: On film and TV production sets, temporary chilled water AHUs are used to control the temperature for both equipment and the comfort of the cast and crew. During the shooting of a movie in an indoor location with limited ventilation, temporary chilled water AHUs can help regulate the temperature.

Construction Sites: Temporary chilled water AHUs are utilized on construction sites to provide cooling for workers in temporary offices, break areas, or other enclosed spaces. A construction site in a hot climate may use temporary chilled water AHUs to create a more comfortable environment in on-site offices and workspaces.

Server Room Cooling: Temporary chilled water AHUs can be employed to provide precision cooling for server rooms during equipment upgrades, maintenance, or emergencies. A company undergoing server room maintenance may utilize temporary chilled water AHUs to ensure that servers and IT equipment remain within optimal temperature ranges.

Emergency Cooling: In emergency situations where a building’s primary HVAC system fails or is under repair, temporary chilled water AHUs can be quickly deployed to maintain cooling. A hospital experiencing a cooling system malfunction may use temporary chilled water AHUs to ensure a comfortable and controlled environment for patients and staff.

Exhibitions and Expos: Temporary chilled water AHUs are commonly used in exhibition spaces to regulate the temperature and humidity for sensitive exhibits or displays. An art exhibition showcasing delicate artworks may deploy temporary chilled water AHUs to maintain optimal climate conditions for preservation.

Data Center Expansion: During the expansion of a data center, temporary chilled water AHUs can be employed to provide additional cooling capacity and maintain ideal conditions for IT equipment. A company expanding its data center facilities may use temporary chilled water AHUs to support the increased cooling demand during the construction phase.

Server Room Upgrades: Similar to emergency cooling, temporary chilled water AHUs can be used during planned server room upgrades to ensure continuous cooling. A company upgrading its server infrastructure may deploy temporary chilled water AHUs to maintain a stable and controlled environment during the upgrade process.

Heat Exchangers

Temporary heat exchangers are versatile devices used in various applications to transfer heat from one fluid to another. These units are often deployed for specific, short-term needs where a more permanent installation may not be practical. Here are several applications where temporary heat exchangers are commonly utilized:

Industrial Process Cooling: Temporary heat exchangers can be used to cool process fluids in industrial settings where precise temperature control is required for manufacturing processes. Such as Cooling hot water used in a manufacturing process to maintain product quality and consistency.

Chemical Plant Shutdowns: During scheduled maintenance or shutdowns at chemical plants, temporary heat exchangers can be employed to manage heat removal or transfer. Using heat exchangers to cool chemicals or control temperatures during equipment maintenance.

Power Plant Outages: Temporary heat exchangers are used during planned outages at power plants to manage heat exchange in various systems. Cooling turbine lubrication oil or managing the temperature of generator cooling water during maintenance.

Construction Site Heating or Cooling: On construction sites, temporary heat exchangers can be utilized to provide heating or cooling for on-site facilities, such as offices and rest areas. Providing temporary heating during winter or cooling during hot weather for construction worker comfort.

Emergency HVAC: In situations where the primary heating or cooling system fails or requires maintenance, temporary heat exchangers can be deployed as part of emergency HVAC solutions. Providing temporary heating for a building during a winter HVAC system failure.

District Heating/Cooling Projects: Temporary heat exchangers can be used during the commissioning phase of district heating or cooling projects or as a backup during system upgrades. Managing the heat transfer in district heating pipelines during the initial testing phase.

Oil and Gas Exploration: Temporary heat exchangers are often employed in oil and gas exploration and production processes to manage heat in various stages of extraction and refining. Cooling hot fluids in the extraction process or managing temperatures in refining operations.

Food and Beverage Processing: Temporary heat exchangers can be used in the food and beverage industry for processes such as pasteurization or cooling during production. Quickly cooling a liquid product before packaging to extend shelf life.

HVAC System Upgrades: During upgrades or modifications to HVAC systems, temporary heat exchangers can help maintain climate control during the transition. Installing temporary heat exchangers to manage heating or cooling in a building undergoing HVAC system upgrade.

Wastewater Treatment: Temporary heat exchangers can be employed in wastewater treatment plants to manage heat in various stages of the treatment process. Cooling wastewater before discharge or heating influent to enhance treatment efficiency.

Direct Expansion (DX) Split Systems

Temporary Direct Expansion (DX) split systems, also known as ductless split systems or mini-split systems, are versatile HVAC solutions that consist of an indoor unit and an outdoor condensing unit. These systems are suitable for various short-term applications where precise temperature control is required. Here are several common applications for temporary DX split systems:

Temporary Offices or Workspaces: Providing heating and cooling for temporary offices, construction site trailers, or other short-term workspaces. A construction site office requires a temporary HVAC solution during the building phase.

Event Tents and Pop-Up Spaces: Cooling or heating temporary structures such as event tents, exhibition booths, or pop-up retail spaces. A company hosting an outdoor product launch event uses temporary DX split systems to cool a tented exhibition space.

Server Rooms and IT Spaces: Providing climate control for temporary server rooms or IT equipment spaces during upgrades, maintenance, or relocations. A company relocating its server room temporarily uses DX split systems to ensure proper cooling for the equipment.

Emergency Cooling: Responding to HVAC system failures by quickly installing temporary DX split systems to maintain indoor comfort. An unexpected failure of the central HVAC system in an office building prompts the use of temporary DX split systems until repairs are completed.

Retail or Commercial Space Renovations: Offering temporary heating or cooling during renovations or remodeling of retail stores or commercial spaces. A retail store undergoing renovations uses temporary DX split systems to keep the space comfortable for customers and workers.

Film and TV Production: Providing localized climate control on film and TV production sets to ensure optimal conditions for both equipment and crew. A film production set in a studio or outdoor location utilizes temporary DX split systems to regulate temperatures during shooting.

Hospitality Suites or VIP Areas: Enhancing comfort in hospitality suites or VIP areas for events, sports venues, or outdoor gatherings. Temporary DX split systems are used to cool VIP tents at a sports event during the summer.

Temporary Classrooms or Educational Spaces: Providing heating or cooling for temporary classrooms, educational spaces, or training facilities. A school undergoing renovations uses temporary DX split systems to ensure a comfortable learning environment.

Server Room Cooling for Events: Cooling temporary server rooms set up for events or conferences. An IT company hosting a tech conference sets up a temporary server room and uses DX split systems for cooling.

Construction Site Cooling: Providing cooling in construction site offices, break areas, or tool storage areas. A construction site in a hot climate deploys temporary DX split systems to cool down on-site facilities for the comfort of workers.

Air-Cooled Package Units

Temporary air-cooled packaged units are versatile HVAC systems designed for temporary or portable applications where heating, ventilation, and air conditioning are needed. These units are compact, self-contained, and suitable for various short-term requirements. Here are several common applications for temporary air-cooled packaged units:

Outdoor Events: Providing heating or cooling for outdoor events such as weddings, concerts, festivals, or sports games. A large outdoor wedding in the summer requires temporary air-cooled packaged units to keep guests comfortable.

Construction Site Facilities: Heating or cooling temporary offices, break areas, or construction site trailers. A construction site where workers need a comfortable environment during breaks or meetings.

Disaster Relief Shelters: Providing HVAC support for temporary shelters during disaster relief efforts. Setting up temporary air-cooled packaged units in emergency shelters for individuals affected by natural disasters.

Film and TV Production: Creating a controlled climate on film and TV production sets to ensure the comfort of crew and actors. Temporary air-cooled packaged units are used on a film set in a remote location where traditional HVAC systems are impractical.

Retail Pop-Up Shops: Offering heating or cooling for temporary retail spaces, pop-up shops, or promotional events. A clothing brand sets up a temporary pop-up shop in a mall and uses air-cooled packaged units for climate control.

Server Room Cooling: Temporary cooling for server rooms during maintenance, upgrades, or relocations. A company relocates its server room temporarily and relies on air-cooled packaged units to maintain the appropriate temperature.

Military Field Operations: HVAC support for temporary military bases, command centers, or field hospitals. Deploying air-cooled packaged units in military field operations to ensure a comfortable environment for personnel.

Trade Shows and Exhibitions: Providing climate control for exhibition spaces during trade shows, conventions, or industry expos. A technology expo uses temporary air-cooled packaged units to maintain a comfortable environment for exhibitors and attendees.

Temporary Classrooms or Training Facilities: Heating or cooling temporary educational spaces, classrooms, or training facilities. A school undergoing renovations uses air-cooled packaged units to ensure a comfortable learning environment.

Oil and Gas Exploration Camps: HVAC solutions for temporary camps set up during oil and gas exploration in remote locations. Providing heating and cooling for personnel accommodations in a temporary exploration camp.

Emergency Cooling for Facilities: Cooling facilities during emergency situations where the primary HVAC system is compromised. An office building facing an unexpected HVAC system failure relies on temporary air-cooled packaged units for emergency cooling.

Festivals and Fairs: Providing climate control for temporary structures at festivals, fairs, or outdoor markets. A summer food festival uses air-cooled packaged units to cool down food preparation areas and vendor booths.

Cooling Towers

Temporary cooling towers are employed in various applications where additional or backup cooling capacity is required for a short duration. These towers are designed to be portable and easy to install, providing a flexible solution for temporary cooling needs. Here are several common applications for temporary cooling towers:

Industrial Process Cooling: Supporting industrial processes that generate excess heat, such as manufacturing, refining, or chemical production. Cooling water used in a manufacturing process during a planned maintenance shutdown.

Power Plant Outages: Providing supplemental cooling during planned outages or maintenance at power plants to ensure continuous operation. Cooling the condenser water in a power plant during a scheduled maintenance shutdown.

Emergency Cooling: Responding to unexpected HVAC or process cooling system failures by quickly installing temporary cooling towers. A commercial building facing an unexpected chiller failure uses temporary cooling towers for emergency cooling.

Data Center Cooling: Supporting data center cooling during maintenance, upgrades, or unexpected failures to prevent overheating of IT equipment. Cooling the water used in a data center’s precision cooling system during equipment upgrades.

Temporary Air Conditioning: Assisting in cooling systems for large-scale temporary air conditioning, especially in events or construction projects. Providing additional cooling capacity for temporary air conditioning units at an outdoor event or construction site.

Film and TV Production: Cooling equipment and maintaining comfortable temperatures on film and TV production sets, particularly in challenging outdoor locations. A film production in a hot outdoor setting uses temporary cooling towers to manage heat generated by lighting and equipment.

Chemical Plant Shutdowns: Supporting cooling needs during planned maintenance or shutdowns in chemical processing plants. Cooling process water in a chemical plant during equipment maintenance.

Refinery Turnarounds: Providing temporary cooling for refining processes during turnarounds or maintenance activities. Cooling hydrocarbon processing units during a planned maintenance period at a refinery.

Construction Site Cooling: Cooling construction site facilities, break areas, or equipment that generates heat. Cooling temporary offices and break areas on a construction site during hot weather.

Special Events: Providing cooling for large-scale events, such as concerts, festivals, or sports gatherings, to ensure the comfort of attendees. A music festival in a warm climate uses temporary cooling towers to manage the heat generated by stage equipment.

Commercial Building Renovations: Supporting cooling needs during renovations or upgrades to a commercial building’s HVAC system. A hotel undergoing renovations uses temporary cooling towers to maintain comfortable temperatures for guests.

Manufacturing Facilities: Supporting cooling requirements in manufacturing facilities during peak production periods or equipment upgrades. Cooling water used in metalworking processes during a high-demand production phase.

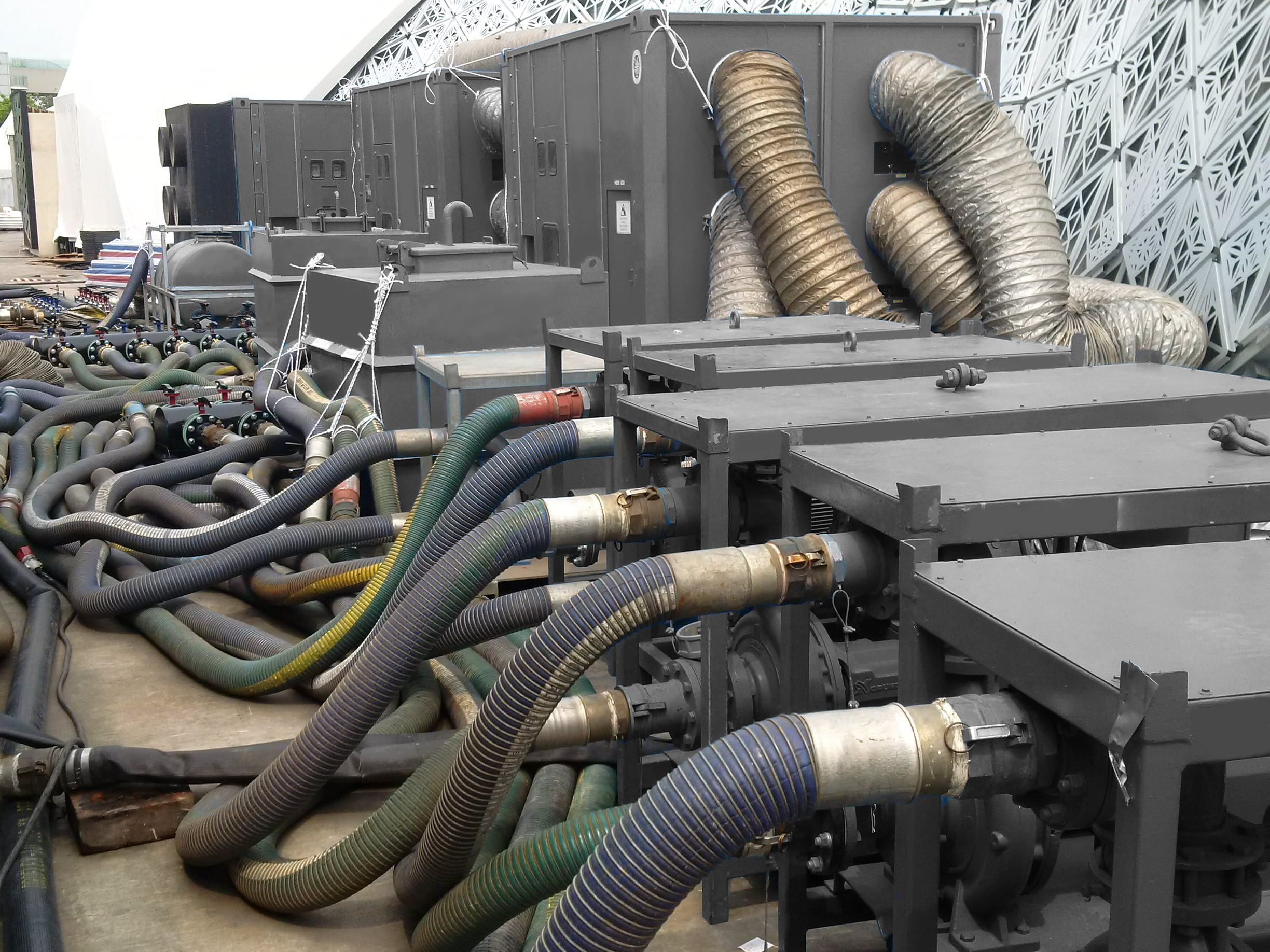

Chilled Water and Condenser Water distribution

Temporary chilled water and condenser water distribution systems are used in various applications where additional or temporary cooling capacity is required. These systems are commonly employed in construction sites, special events, emergency situations, or during planned maintenance. Here are several common applications for temporary chilled water and condenser water distribution:

Construction Site Cooling: Providing temporary chilled water distribution for air conditioning systems on construction sites to ensure a comfortable working environment for workers. Temporary chilled water piping is used to cool air handling units in construction site offices and break areas.

Event Cooling: Offering temporary chilled water distribution for air conditioning in large event venues, such as convention centers, exhibition halls, or tents. A trade show held in a convention center uses temporary chilled water distribution to cool various exhibition spaces.

Server Room Cooling during Maintenance: Implementing temporary chilled water systems to cool server rooms during planned maintenance or upgrades. A company performing maintenance on its primary HVAC system uses temporary chilled water distribution to cool server rooms.

Emergency HVAC: Responding to unexpected HVAC system failures by quickly installing temporary chilled water systems to maintain cooling. An office building facing a sudden chiller failure uses temporary chilled water distribution to avoid disruptions.

Film and TV Production: Providing temporary chilled water distribution for cooling equipment on film and TV production sets, especially in outdoor or remote locations. A film production set in a hot outdoor setting uses temporary chilled water distribution to cool lighting and production equipment.

Commercial Building Renovations: Offering temporary chilled water distribution to support cooling needs during renovations or upgrades to a commercial building’s HVAC system. A hotel undergoing renovations uses temporary chilled water piping to maintain cooling in guest areas.

Temporary Classrooms or Training Facilities: Providing temporary chilled water distribution for air conditioning in temporary educational spaces, classrooms, or training facilities. A school using temporary classrooms during renovations relies on chilled water distribution for cooling.

Data Center Cooling during Expansion: Implementing temporary chilled water distribution to cool additional server rooms or data center expansions. A company expanding its data center uses temporary chilled water systems to support the increased cooling demand.

Special Events: Providing temporary chilled water distribution for air conditioning in temporary structures at special events, such as weddings, concerts, or festivals. An outdoor wedding held in the summer uses temporary chilled water distribution to cool tents and event spaces.

Hospitality Suites at Events: Offering temporary chilled water distribution for air conditioning in hospitality suites or VIP areas at events or sports venues. Cooling hospitality suites during a sports event using temporary chilled water distribution.

Emergency Cooling for Critical Facilities: Implementing temporary chilled water distribution in critical facilities, such as hospitals or data centers, during emergency situations. A hospital facing a cooling system failure uses temporary chilled water distribution to ensure a stable environment for patients.

Cooling for Oil and Gas Exploration Camps: Providing temporary chilled water distribution for air conditioning in temporary camps set up during oil and gas exploration in remote locations. Cooling accommodations for personnel in a temporary exploration camp in a hot climate.

Desiccant Dehumidifiers

Temporary desiccant dehumidifiers are utilized in various applications where controlling humidity levels is crucial. These units are effective in removing excess moisture from the air, making them valuable in situations where maintaining specific humidity conditions is necessary. Here are several common applications for temporary desiccant dehumidifiers:

Water Damage Restoration: Accelerating the drying process in buildings affected by water damage, such as floods or leaks. After a water pipe burst in a commercial building, temporary desiccant dehumidifiers are used to prevent mold growth by rapidly removing excess moisture from the air.

Construction Drying: Assisting in drying newly constructed buildings or spaces by controlling humidity during and after construction. A newly constructed office building uses temporary desiccant dehumidifiers to speed up the drying of paint, plaster, and other construction materials.

Pharmaceutical and Electronics Manufacturing: Maintaining low humidity levels in manufacturing processes where humidity control is critical for product quality. A pharmaceutical manufacturing facility uses temporary desiccant dehumidifiers to control humidity during the production of sensitive medications.

Cold Storage Facilities: Reducing humidity in cold storage areas to prevent frost buildup and maintain optimal conditions for stored goods. A temporary cold storage facility for perishable goods uses desiccant dehumidifiers to control humidity and prevent moisture-related issues.

Mold Remediation: Controlling humidity levels during mold remediation projects to inhibit the growth of mold spores. In a building with a history of mold issues, temporary desiccant dehumidifiers are employed during mold remediation to create unfavorable conditions for mold growth.

Museum and Archive Preservation: Protecting valuable artifacts, documents, and artworks by maintaining controlled humidity levels in museums and archives. A museum undergoing renovations uses temporary desiccant dehumidifiers to preserve its collection during periods of high humidity.

Food Processing and Storage: Controlling humidity in food processing facilities and storage areas to prevent spoilage and maintain product quality. A temporary food processing plant uses desiccant dehumidifiers to control humidity during the processing and packaging of food products.

HVAC System Drying: Assisting in the drying of HVAC systems after water damage or during maintenance to prevent mold growth. A commercial building with a water-damaged HVAC system uses temporary desiccant dehumidifiers to dry the ductwork and prevent microbial growth.

Power Plant Outages: Controlling humidity during planned outages at power plants to prevent corrosion and maintain the integrity of equipment. A power plant undergoing maintenance uses desiccant dehumidifiers to control humidity levels in critical areas.

Temporary Server Rooms: Maintaining controlled humidity in temporary server rooms or data centers during events or construction projects. A company hosting a temporary IT event uses desiccant dehumidifiers to ensure optimal conditions for servers and IT equipment.

Film and TV Production: Controlling humidity on film and TV production sets, particularly in environments where traditional HVAC systems may not be sufficient. A film production in a humid outdoor location uses temporary desiccant dehumidifiers to protect equipment and ensure a comfortable working environment.

Textile and Paper Manufacturing: Maintaining low humidity levels in manufacturing processes where moisture control is crucial for quality control. A temporary textile manufacturing facility uses desiccant dehumidifiers to control humidity during the production of fabrics.